The rolls are wide and also make it for less seams. As in Modified Bitumen rubber roofs the seams are heat welded. We do not recommend this type of membrane due to the fact it is very hard to repair and not every roofer or handyman has the knowledge to work with this material.

The benefit of such a roof is that the installer must be certified by the manufacturer. The manufacturer also then gives the guarantee to the roof after they checked it.

The Pro’s and Cons of a EPDM roof and a Modified Bitumen roof.

TPO roof

The benefits of Modified Bitumen Membranes outweigh that of EPDM rubber roofs by far.

Flat Roof Repair – “How to locate a flat roof leak”

Flat Roof Repair – How to Fix a Leaky Flat Roof – DIY Guide covers all three types of Roofing Repairs – EPDM Rubber, TPO Vinyl, and Modified Bitumen Torch Down Roofing. This includes:

- Determining what type of flat roof you have

- Locating the leak on your flat roof

- Repairing flat roofing membranes – EPDM Rubber – TPO Vinyl – Torch Down Rubber

- Determining whether Flat Roof Repair is cost effective

- Follow the “How to Fix a Flat Roof Guide”

DIY Flat Roof Repair Checklist

- Step 1 – Determine what type of flat roof repair you need to make by determining the roofing materials – is it an EPDM, TPO, Tar, and Gravel or a Torch Down?

- Step 2 – Find out how old the roof is – EPDM, TPO do not last much longer than 15 years. Torch Down can continue indefinitely

- Step 3 – Look for apparent problems around vents, drains and other objects

- Step 4 – Check the pitch pockets, flashing, cracked skylights, storm damage, holes made by flying debris from a storm

- Step 5 – Clean or wash the roof to expose issues easier

- Step 6 – Clean out drains and gutters regularly

- Step 7 – Apply compatible sealant where holes, cracks are visible causing leaks

- Step 8 – Replace broken skylights and vent boots

- Step 9 – Find an experienced roofer – not a handyman, to make the necessary repairs

This Video is about “How to Repair a Flat Roof” that has a Torch Down Rubber membrane. Follow the links to see how to make flat roof repairs on different roofing materials.

This video shows how a pitch pocket could cause a leak on a flat roof.

It is not always easy to locate what causes a leak on a flat roof. From experience, we know flashing against brick walls, chimneys are very susceptible causing leaks. Pitch Pockets on commercial roofs are know for causing leaks. Watch the video to see how to look for a leak and then what you are supposed to do to fix a flat roof leak.

DIY Flat Roof Repair support is available in all states:

- Connecticut

- New York

- Rhode Island

- Pennsylvania

- Texas

- Massachusetts

How to “Repair a Flat Roof Guide” – Follow the Instructions and make a list of things to do

Flat Roof Repair can be as easy as using s little caulk or tar. Finding the leak can be a problem. Look for the obvious. Things that can be obvious are places like flashing, vent pipes, drains, skylights. It should be relatively easy to spot a problem if there is a leak.

When it comes to seams, then it is harder to find a leak in the roof. This takes an experienced eye to detect a leak.

A list of places to look where a possible leak on the flat roof can be:

Flat Roof Repair is easy to perform. Once you have located the problem area. To make a flat roof repair, very few tools are required and the cost of repairing is minimal.

1. Skylights on flat roofs

Making Skylight Repairs on a flat roof can be tricky. Here are a few tips where you can begin. Check the following on a skylight:

- Skylight flashing – make sure that the rubber membrane has not come loose from the metal flashing. In some cases, the rubber membrane is the flashing as well and is tucked underneath the skylight frame. In other circumstances, the membrane is attached to the skylight flashing. Pull up on the membrane and see if you can lift it from the flashing. It should be tight and secure

- Skylight Dome and Frame – when the glass or plexiglass dome of the skylight is secured with a metal frame, then it is likely that the rubber gasket that seals between the glass and the frame has dried and cracked

This 3 D video shows where an EPDM Rubber Membrane can leak

- Corners on skylights – In many cases where the rubber membrane is galvanized around the corners of the skylight, can cause leaks due to the seams separation

- Cracked Plexiglass – The plastic or plexiglass domes on skylights crack due to ultralight exposure

A List of Manufacturers of Skylights:

The image above is a Round Domed Skylight made by Wasco

2. Bathroom Vent pipes – Flat roof repairs

Vent pipes piercing through a rubber membrane can become the cause of a flat roof leak. The rubber gasket or “roof boot” deteriorates over time and crack causing the leak.

- Check the “roof boot” around the vent pipe

- Check the rubber membrane and seams that attaches to the metal flange of the “roof boot”

- Sometimes the “tar” that is used to seal the pipe to the rubber, gets dry and crack, causing the leak

Bathroom Vent pipe with a Roof Boot – To make a flat roof Repair, you need to identify the leak areas. The vent pipes are prone to leak.

3. Pitch-Pockets on flat roofs causes leaks

A Pitch-Pocket is a bottomless container that is placed on a flat roof where airconditioner pipelines and wires are fed through. After the wires and pipes are fed through, the container is filled with liquid “tar” or roof cement to seal around the wires and pipes.

- Check the pitch-pocket and see if it is full to the brim with tar. Many times this tar will dry and shrink and cause a low spot in the container. When it rains, this low spot will collect water, and water will eventually leak through where the wires and pipelines are.

- Check the foam insulation that covers the pipelines. This foam deteriorates and causes openings where water can leak through the Pitch-Pocket.

- As a precautionary step, these pitch-pockets should be filled to the brim at least once a year.

- When looking for a leak on a flat roof, always check the pitch pockets to see if the tar in them is filled to the brim.

- Flat Roof Repairs can easily relate to a Pitch-Pocket that has wires and pipes going through it, and all you need to do is make sure the insulation foam around the pipes is not the cause of the leak.

An Example of a Pitch pocket with Tar. Notice the foam insulation around the pipes is all torn. This cause leaks on flat roofs

4. Flashing on flat roofs causing leaks

Flashing is probably the biggest cause of flat roof leaks. Many roof technicians will not take their time and make a proper flashing transition from a rubber membrane to flashing. This can be attributed to lack of experience or did not charge enough for the job.

Locating flat roof leaks – This video points out how counter flashing, if not done right, can cause a leak.

- Counter flashing – whenever flashing is used where a roof meets a wall, there must be proper counter flashing. Counter flashing is when siding or stucco or any other methods are used to cover the flashing from the top side. One should never be able to see the edge of a flashing.The vertical section should be covered by stucco, wood siding, or even other metal. The horizontal part that lies flat on the roof, should be covered by the rubber membrane.

- Test the rubber adhesion on the metal – try to pull the rubber membrane away from the metal, if it comes up easily, then that could be the cause of the leak.

- Check for cracked stucco or siding – If the siding or stucco has cracks in it, then the counter flashing is compromised.

Installing Counter Flashing – To fix the roof leak on this flat roof we had to install counter flashing. We used an angle grinder to cut a slot into the wall where the metal flashing can be inserted.

Flat Roof Repair – Installing Counter Flashing

The brick wall in the image shows that the membrane was brought up the wall about 12 ” high. They then adhere the roofing membrane to the wall. This way of making flashing doesn’t work. The membrane will eventually pull away from the wall. We cut a slot into the brick wall at a 30 degrees angle.

After the slot was cut, we inserted a metal counter flashing that hang over the membrane. This is what counter flashing is and how it is done.

Flat Roof Repairs mostly involves flashing on flat roofs that were not done correctly.

Counter Flashing Installed – After cutting the slot into the brick wall, a metal flashing was inserted into the slot and that went over the membrane to cause the flashing.

5. Chimneys – the Cause of Flat Roof Leaks

The counter flashing on chimneys is always a problem on chimneys. Many times, the counter flashing has to be embedded in the stone or brick wall. This is where most people don’t get it right.

- Check if the sealant that is used on the counter flashing still holds

- Check if the counter flashing is still intact

- Check for cracks in the chimney

- Inspect the chimney crown – This is the topmost part of the chimney – Most of the time, these cement slabs crack and causes leaks.

- Make sure the rubber membrane is properly attached to the flashing on the chimney.

In the image, notice where the metal flashing meets the cement grout. That little crack is where water leaks from on a flat roof

Chimney flashing causing leaks – to be able to fix flat roof leaks, you need to identify what causes the leaks. See the flashing in this image

7. Drains – Flat roof repairs around drains

When a drain is leaking, it is not always necessarily what causes the leaking. Because the drain is normally lower than the rest of the roof, a leak could start somewhere else and flow towards the drain underneath the roof membrane.

To locate a leak around a drain area do the following:

- Try to open the ceiling where the drain is coming through the roof and make a visual inspection

- Clean all debris that has accumulated around the drain and strainer

- Remove the strainer to make a visual inspection of the drain pipe from above

- Make a close-up inspection of the roofing membrane and the drain flange to see if it hasn’t separated

- If you cant find an obvious problem, call an experienced roofing technician to find and repair the leak

Flat Roof Repair – The rubber membrane was never attached to the drain flashing in this image

8. Dripedge – Locating the roof leak at the perimeter of the roof on the drip edges

Drip edges are made of metal and make the transition from the roofing membrane to the gutter or edge of the roof

Things to inspect to see if the drip edges are causing roof leaks:

- Inspect to see if the membrane is still attached to the metal edging on the perimeter of the roof

- Check where two drip edges overlap for a potential gap or crack on the roof

- Make sure the drip edges are still properly attached to the substrate

- If gutters are present, make sure the drip edges are pointing into the gutter and not behind the gutter

Below are links to the different types of roofing membranes that you might have and want to repair yourself.

Flat Roof Drains

- Other Articles:

- Flat Roof Drains

- Scuppers

- Gutters

- Drain Strainers

- 3D Video designing a perfect drain

- Ice and gutters

General Roof Repairs

- Fixing a leaky post on a deck

- Leak Repairs on Flat Roofs

- Flashing and Siding cause leaks

- When not to repair a flat roof

- Valley Flashing – repairs

These articles are to help you to identify …

More Flat Roof Repairs

Rubber Membrane Repair Torch Down – DIY Videos

- Main Page: Torch Down Rubber Membrane Repair

- Other Articles:

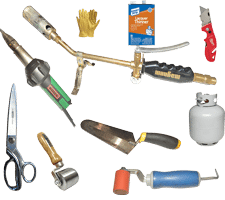

- Materials and Tools list with instructions to fix a Torch Down Rubber Roof

- What to look for before making roof repairs

- Comparing Torch Downs with other Roof systems

- Aluminum …

More Flat Roof Repairs

Metal Roof Repair

- Fixing and Recovering an old metal roof

- Our method patching it with rubber

- Showing silicone spray destroying a metal roof

- Installing a Rubber Roof over a metal roof

Cost effective Metal Roof Repairs Many old …

More Flat Roof Repairs

TPO Vinyl Membrane Repair

- Main Page: How to repair a TPO membrane

- Other Articles:

- TPO and PVC Roofing – Single Ply Roofing System

- Advantages and Disadvantages of a TPO roof

- TPO Roofing membrane

- Fixing a TPO …

More Flat Roof Repairs

Silver Coating or Aluminum Coating

- A video explaining the “Silver Coating”

- Advantages and Disadvantages

- Stone or Rock used for UV protection

- Embedded Ceramic Granules for coating

- How to apply the coating to a rubber roof

Silver Coating Silver Coating …

More Flat Roof Repairs

EPDM Rubber Roof Repair

- Main Page: DIY EPDM Rubber Roof Repair instructions

- Other Articles:

-

- Comparing EPDM Rubber with Torch Down

- Explaining three types of Rubber membranes

- Ultra Violet Degradation of EPDM Rubber

- EPDM Rubber Roof Issues

…

Skylight Repairs

- How to fix a skylight leak

- Flat Roof Leaks caused by skylights

- What cause a skylight to leak

- Different Style Skylights for flat roofs

- Replacing a gasket on a skylight

Skylight Repairs on Flat …

More Flat Roof Repairs

Chimney Repairs on Flat Roofs

- How to seal a Chimney Leak

- Repair and Maintenance of a Chimney

- Chimney Grout and Repointing

- Chimney Leaks – how to find and fix them

- Flashing on a chimney causing a leak

Fixing or Repairing Chimneys …

More Flat Roof Repairs

How to Determine the Type of Flat Roof Membrane to make roof repairs

- EPDM Rubber Membrane – you can tell it by the …

More Flat Roof Repairs

We have been fixing flat roofs for over thirty years in these towns of Fairfield County.

We serve Connecticut :

- Greenwich

- Stamford

- Darien

- Norwalk

- Westport

- Fairfield

- New Canaan

- Ridgefield

- Weston

We have a base in Pennsylvania where we have been installing and Repairing Flat Roofs.

We serve Pennsylvania in the following towns:

- Latrobe

- Greensburg

- Jeanette

- Monroe

- Pittsburgh

- Harrisburg

- Altoona

We have a base in Texas where we have been installing and repairing flat roofs for the last twenty years.

We serve the North East Texas corner in the following towns:

- Longview

- Tyler

- White Oak

- Kilgore

- Marshall

- Gilmer

- Jefferson

Below are the Three images of the Three Different Types of Roofing membranes found on flat roofs

Torch Down Rubber Membrane

This is what a Torch Down Rubber membrane looks like. The membrane come in three foot wide rolls and the seams are fused together with a torch.

When making flat roof repairs on a Torch Down Roof, you can use any petroleum product as in tar, butyl caulk. This roof in the image has a white granular embedded on the surface to protect it from ultraviolet rays.

Many times a plain torch down membrane is installed with no granular, then a silver coating must be applied to protect it.

Torch Down Rubber Membrane – Fixing flat roofs and making repairs Westport, CT

EPDM Rubber Roof Membrane

This is what an EPDM Rubber Roof Membrane looks like. It is black, and have a smooth surface. The seams can be from ten feet to twenty feet apart. When you need to make flat roof repairs on an EPDM rubber membrane, the first thing to check is the seams. The adhesives that are used to bond the seams together, prematurely fail, due to the extreme heat and ultraviolet.

The adhesives that are used to bond the seams together, prematurely fail, due to the extreme heat and ultraviolet. EPDM rubber roofs generally don’t last more than 8 years without severe issues and repairs.

EPDM Rubber Roof Membrane – Repairing, patching and making EPDM Rubber flat roof repairs

TPO Roof Membrane

This image shows what a TPO Roof Membrane looks like. These roofs are generally good and will last up to 20 years. It is a better roof than that of an EPDM Rubber membrane but it is still susceptible to ultraviolet rays. In the video above I showed how the TPO Roof is at its end due to ultraviolet degradation.

TPO Roof Membrane – Mending and fixing flat roofs is what we do. Patching TPO membranes